Our Sterilization Process

The process of ozone sterilization is exceedingly effective and remarkably simple.

By combining the powerful oxidizing properties of ozone with the mechanical processes of medical waste shredding systems, Clean Waste Systems’ processing solutions comprehensively sterilize medical waste.

Clean Waste Systems Ozone Sterilization Process

The sterilization process is pictured on the OMW-400. The OMW-1000 follows a similar process.

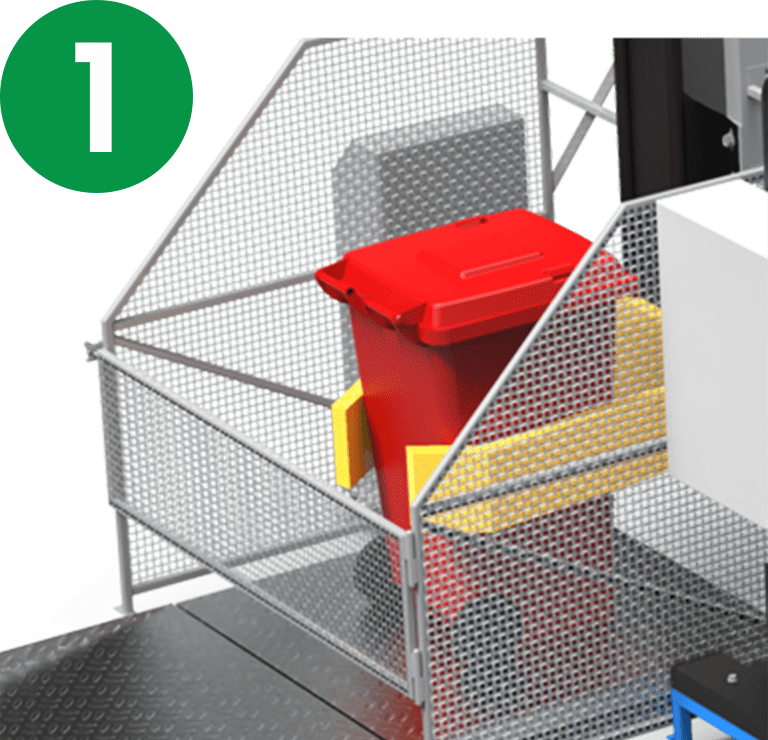

Waste container is rolled onto the system’s lifting mechanism.

Processing begins with the push of a button. Waste is weighed, lifted and documented.

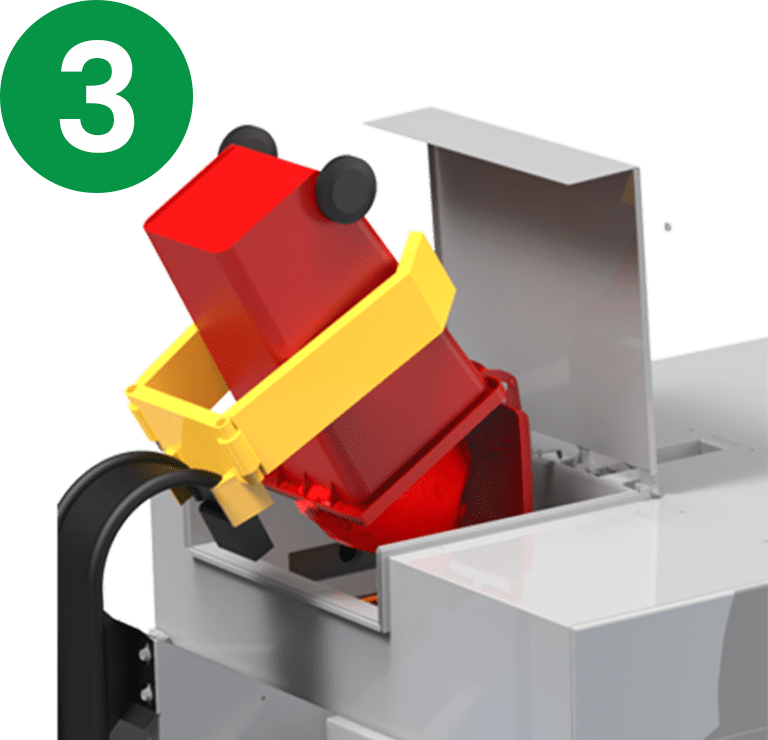

A door automatically opens to allow the waste to be tipped into the shredding mechanism.

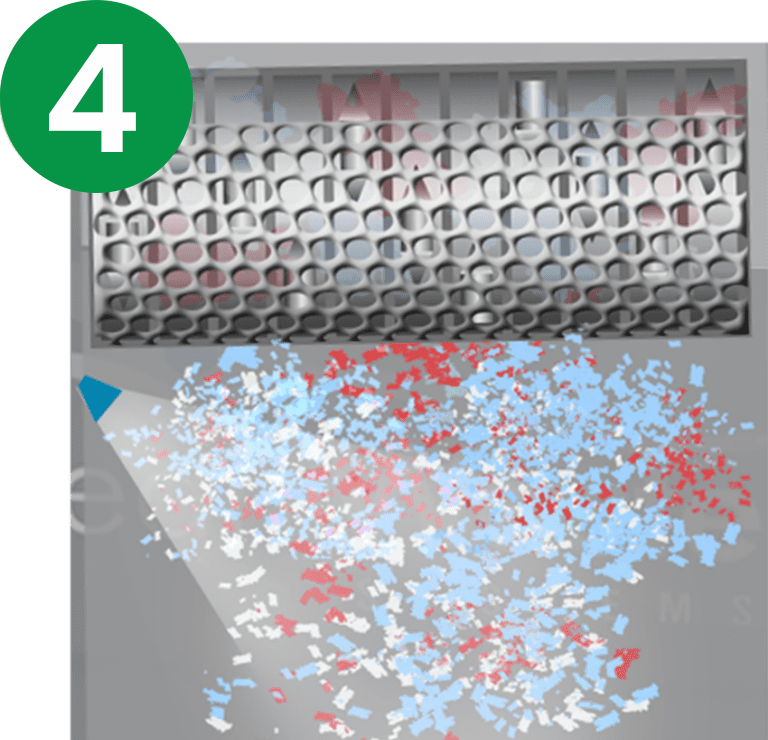

A heavy-duty industrial power shredder breaks apart the waste, reducing its volume by 90%.

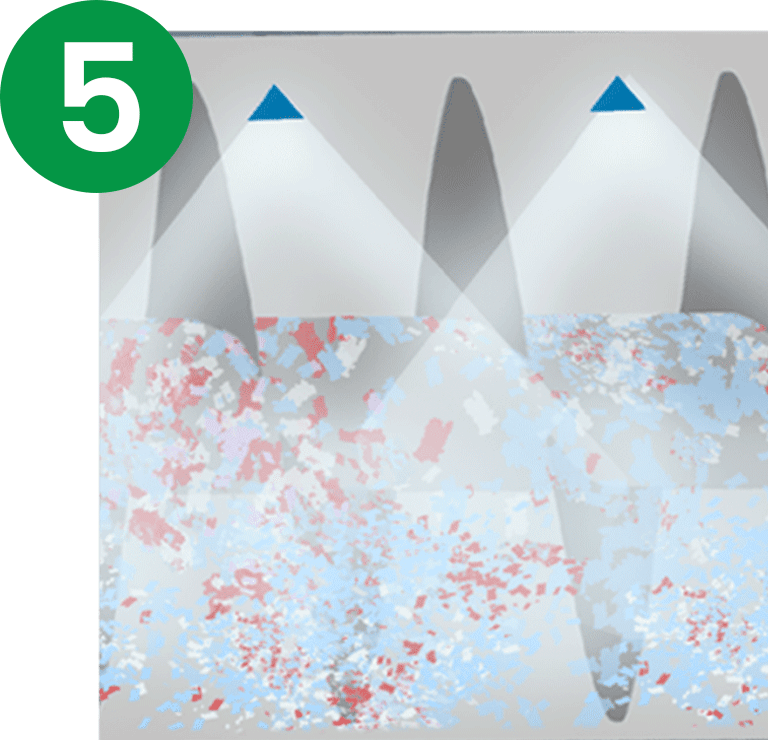

The shredded waste is exposed to our patented Humidizone® humidified ozone formula, which comprehensively sterilizes the waste and greatly reduces odor. The ozone sterilization process produces zero emissions or hazardous fumes and uses no chemicals, steam or heat.

Now completely sterilized and inactive, the shredded waste is transferred to a sanitary landfill. The physical volume of waste is greatly reduced, allowing for fewer trips to the landfill and a significantly improved carbon footprint.

Explore our Medical Waste Systems

Learn More About Ozone Sterilization

Contact the Clean Waste Systems team to learn more about taking your medical waste treatment in-house simply, safely and sustainably through our groundbreaking ozone technology.